If you’re a businessman, you are aware how essential effectiveness is in terms of running a effective functioning. How you will create your store’s assembly series can easily make a big difference in productivity and earnings. On this page, we’ll discuss guidelines for optimizing your store assembly (butiksmontage) for max performance and exactly how it may gain your organization in the long run.

1. Evaluate Your Store Format

The first and foremost issue you have to do would be to examine your store structure. This will help to determine any potential bottlenecks or places that upgrades can be done. This can be accomplished simply by following the movement of traffic with your store and how customers transfer from a single area to another one. This will allow you to rearrange your store format in order that assembly jobs are performed more effectively.

2. Standardize Procedures

The next thing is to standardize your store’s assembly processes. This requires deteriorating each project into more compact, far more controllable actions that can be quickly combined with your staff. After each job is consistent, develop a guideline or handbook that describes all things in fine detail. This will remove misunderstandings and be sure that the identical approach is followed every time.

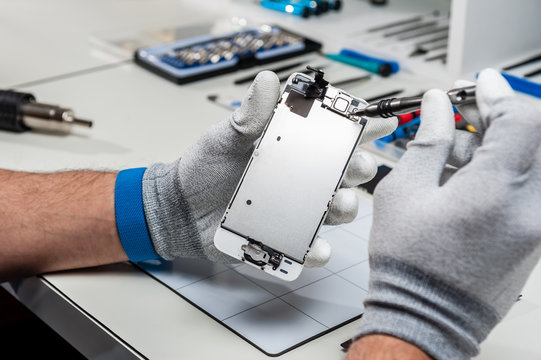

3. Invest in the Right Devices

Having the proper equipment is required for improving your store’s assembly efficiency. From hands trucks and pallet jacks to conveyor straps and computerized devices, there are many forms of gear open to make assembly duties easier and faster. Buying the best products may need some upfront costs, nevertheless it pays off in the end by raising productivity and lowering work fees over time.

4. Coach Your Group

One more key factor in optimizing store assembly is personnel training. Be sure that your group is correctly qualified on all assembly activities and knows ways to use the gear successfully. Offer typical education and feedback in order to carry on and improve and function better. Cross-training your workers may also stop bottlenecks and make sure that you use a well-curved group that will multitask if needed.

5. Ongoing Development

Finally, look for methods to increase your store assembly processes. Regularly review your assembly series and check out possibilities to improve activities, lessen squander, and boost efficiency. Inspire your staff to offer comments and get their ideas into consideration. Constantly increasing procedures will not only gain your store’s assembly line and often will also positively affect your entire enterprise.

Simply speaking

Improving your store assembly for optimum performance demands a combination of analyzing your store structure, standardizing procedures, investing in the proper gear, training your team, and continuously improving your assembly procedure. By utilizing these techniques, you can dramatically raise productivity and profitability with your company. Don’t forget about the significance of efficiency and consider the required actions to ensure your store assembly operates effortlessly.